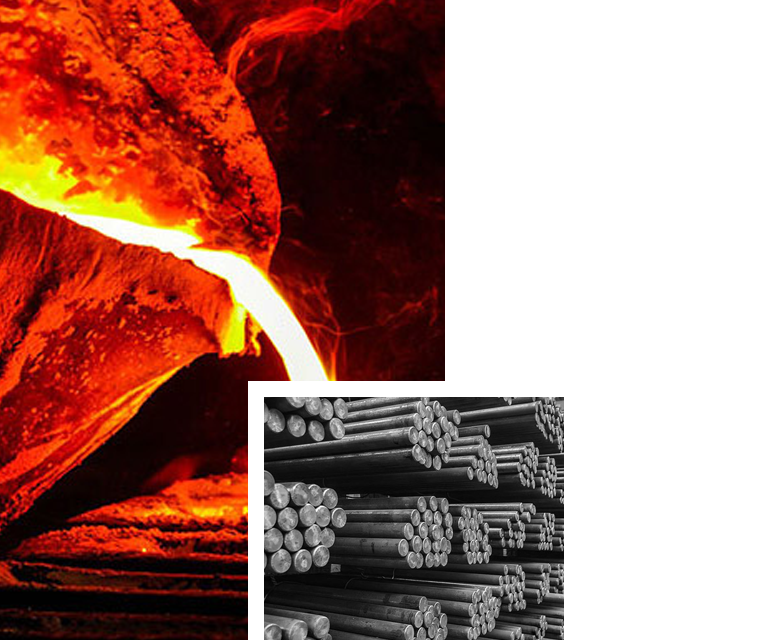

The skyway story began with the setting up of skyway steel industries in 2005 as a steel unit rolling steel rounds and RCS. From the very start, skyway always endeavoured to produce the highest quality material. As such there was always an underlying requirement for in house melting shop, which was met with the incorporation of Steeltech Alloys Pvt Ltd. in 2014. In the recent years, operating in the special and precision steel segment of the industry, the group established skyway components in 2017, a state of the art steel processing unit.

"Steeltech Alloys Pvt Ltd" is a melting shop with an installed capacity of 40,000 mt per annum. The route of steel making is through induction furnace melting with refining through Vaccum Degassing {vd).

"Skyway Steel Industries" is a steel plant with an installed capacity of 60,000 mt per annum. The company manufactures carbon, alloy and special steels in on figurations of Steel Rounds, RCS and Hex.

"Skyway Components" is a technologically advanced steel processing unit with an installed capacity of 24,000 mt per annum. The facilities include annealing, drawing after shot blasting, peeling, grinding and polishing, Heat Treated & Threaded Bars. The company has a state of the art laboratory and testing facilities and serves as the R & D Centre for the entire group.

"SKYWAY ISPAT" is a state of the art steel melting shop started in 2026 with an installed capacity of 60,000 mt per annum. The route of steel making is through induction furnace melting with refining through Ladle refining furnace (LRF) and Vaccum Degassing {vd) to produce very high quality prime steels.

Year Of Experience

Good Relation Built

Our mission is to deliver and supply the most noteworthy quality products to our clients utilizing sustainable procedures that meet the most elevated global standards of environmental control. We trust that profoundly talented and motivated employees are the way to accomplishing our goals and we will keep on providing outstanding training and investment in their future.

Our vision is to participate consistently in extending our generation limits and expanding our production capacities with a specific end goal to meet the epidemically developing worldwide demand and therefore hold our position at the front of the steel business.

© 2026 Skyway Steel Industries. All Rights Reserved.

Website Designed & Developed By: Cyberxel